My printers can manage ALL kind of filaments....

PLA, PLA+, ASA, PETG, ABS, etc.. and also with reinforcements or add-ons like WOOD and CARBON Fiber!

The possibilities are endless, just you're limited by availability!

You want a yellow elephant, or a pink dashboard cover? You name it!

Need a sparepart what is Heat resistant (ABS)? just contact me!

Need abbrassive tooling materials (Carbon fiber reinforced)?.... i can deliver!

The printerbed is 257 x 257 mm, the printspace is 257mm high.

Parts bigger than these dimensions can be made in multiple parts.

It can be assembled by glue or by fixture inserts! Some

print designs provide a kind of "click in" system which are also very good alternatives!

Inserts are available from M2 until M5 in various lenghts.

By default the inserts are made of brass and the bolts are steel.

If desired, it is possible to use stainless steel (wet environtment) bolts

and stainles steel inserts, but has to be ordered

Allthough the Bambu Labs X1C is the fastest desktop 3D printer right now on the market, the speed is ALWAYS depending on the diameter of the printline (nozzle diameter) and the printing materials!

With PLA+ this printer can speed up to 10.000 mm2/sec! This is more than 5x the speed of the average 3D printer. Prototyping in PLA is therefore recomended if time is an issue!

Abbreassive materials and heat resistant materials need much higher printing temperatures! The result is a smooth and a strong object, but has to be printed way much slower to become this good!

Printing wood is a risky business! Woodparticles and splinters can clogg the default nozzle (0,4mm) and should be printed with bigger nozzle sizes like 0,6 or 0,8mm This means that more material is used to reach the same size of object when printed with PLA. More material means slower printspeed!

So expecting me to print a final object in ABS in the same speed as the prototype went in PLA+ is not realistic and also not possible!

I do support both ways of printing jobs.

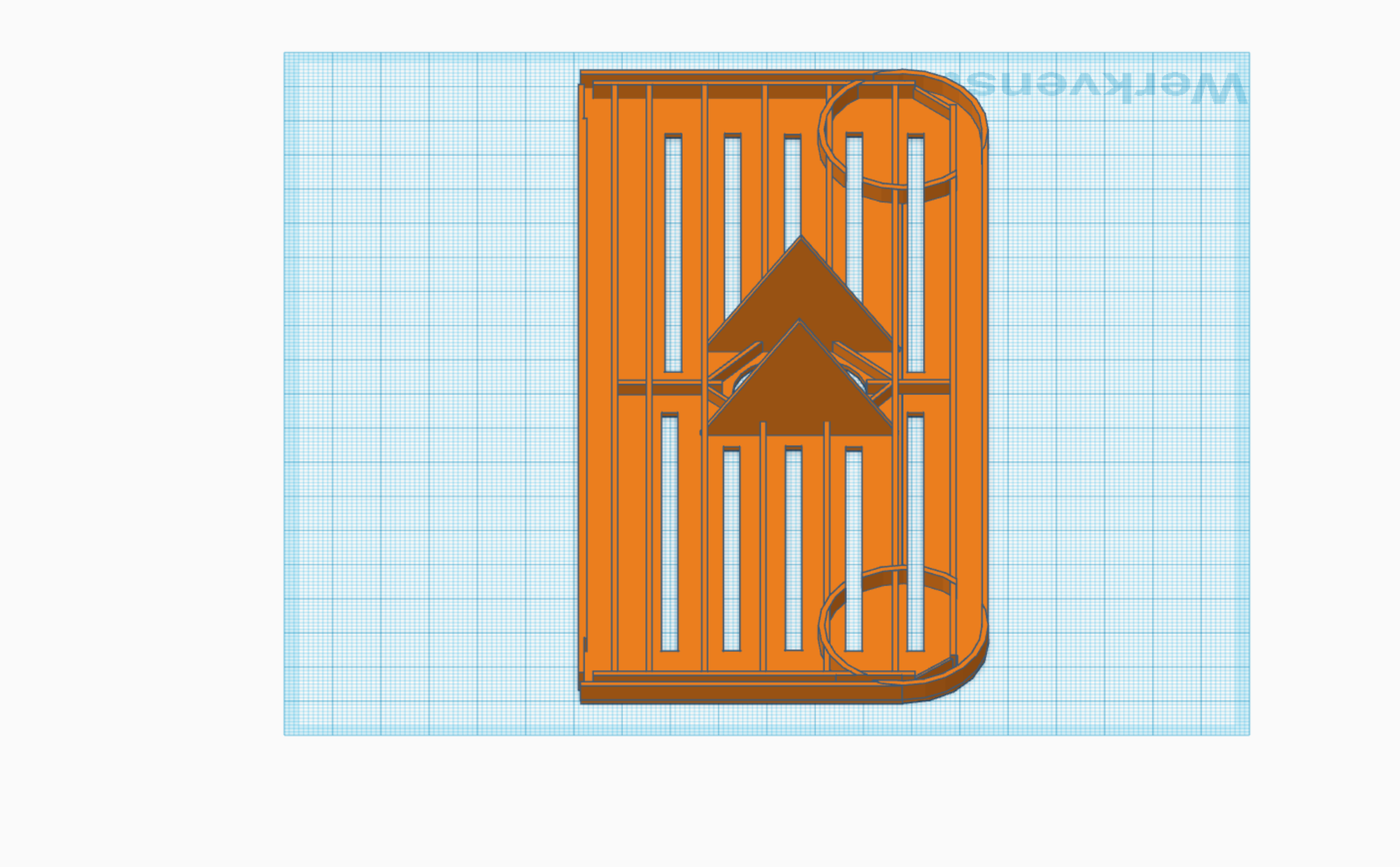

The "ready designs" means you deliver the files

with the design, which are ready to be read by

the printer so the printjob can start almost

immediately.

The "custom designs", means you deliver the

drawing or the original part. Just you have

to understand that with custom designs a

lot of time is necessary with drawing,

prototyping, testing and interactions with you.

3DFix has the capability to do customs design

for you and would love to take this over from

you, just be aware this costs more time, energy

and materials (because prototyping), so the price

differs from "ready designs"